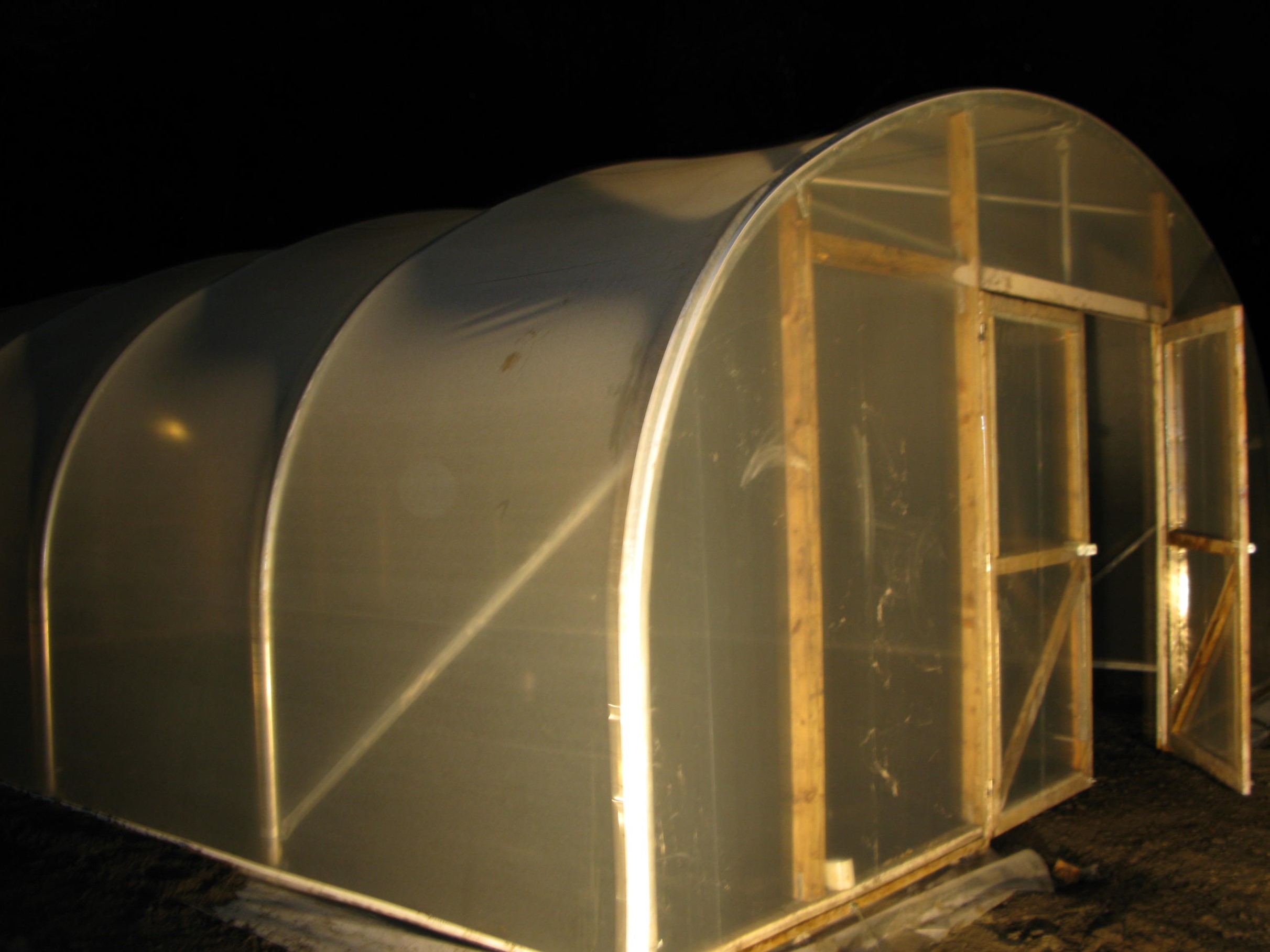

Polytunnel 7m x 20m

Our 7m wide Polytunnel is extremely robust with long foundation tubes that sleeve inside the straight legs of the hoops to strengthen them and 60mm high tensile steel hoops (2mm wall) at 2m centres. Our steel tube is Magna Coated which is a step above normal pre-galv tube, offering up to 20 times more corrosion resistance. Polydome Polytunnels are an investment in durability and quality.

Please note when sizing a plot of ground for a Commercial Polytunnel we recommend you add at least 4m to the width of the Polytunnel and 6m to the length. See more detail in the Siting and Preparation section.

Gallery

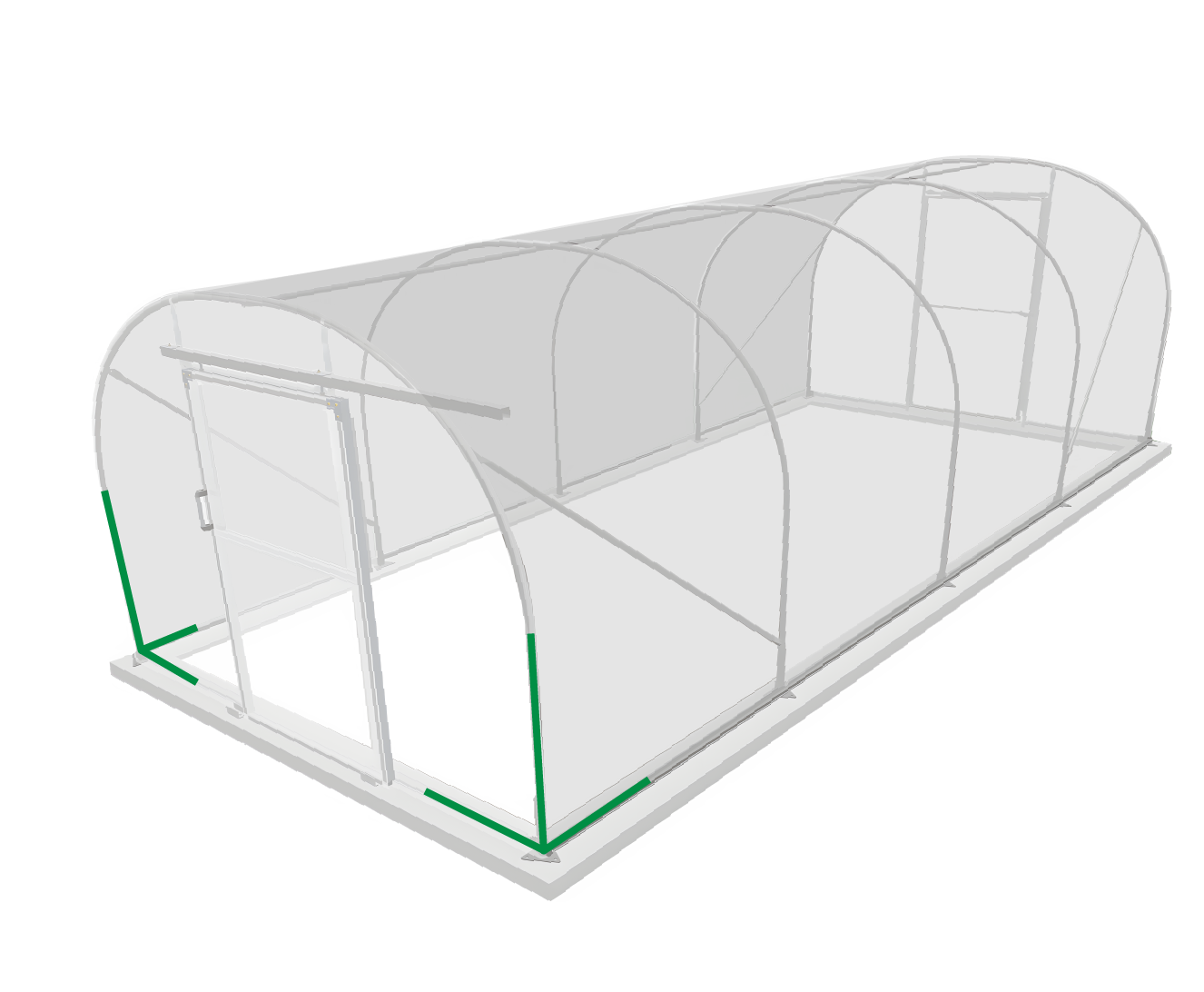

When sizing a Polytunnel for a plot of ground we would recommend you add at least 4m to the width of the Polytunnel and 6m to the length. This is for room to dig trenches, avoid snagging your cover on obstacles, good ventilation, allow run off water to drain away, room for unrolling the polythene at the gables during covering etc.

Avoid siting below trees as the run-off water from them will make the tunnel very dirty regularly and the tunnel may well be damaged from time to time by debris falling from the tree in storms.

The best orientation for strength is to face your gable end towards the prevailing wind, if you have a slope on the site run the length of the tunnel down the slope. With these Polytunnels the ground must not have more than a 10cm slope across the width of the tunnel – unless you order a custom model designed to accommodate the slope (but generally it is a good idea not to have a slope across the width as you will have gaps below doors and other issues, so it’s better to level the ground instead).

If installing the Polytunnel on soil – the foundations are normally dug to a depth of 60cm (but allow a bit more for enthusiastic digger driving). Make sure if you have any pipes or cables crossing the site to mark their exact position and know the exact depth of them so that when building your Polytunnel they are not damaged.

- Straight Sided – more useable space inside.

- High Strength Design – an investment in quality is never regretted.

- Cover tensioning system – your polythene cover can be easily tensioned in warm weather prolonging its life.

- Configurable Design – Design your Polytunnel to suit your requirements.

- Simple construction – any handy DIY person should have no problem to install it.

- Good back up support for self-construction – tech support over the phone, videos, instructions.

- For Horticulturalists – improves plant quality, growth and yield.

- Can be configured for multiple uses (sheep farmers, Garden Centre Canopies etc.

Our steel tube is primarily ‘Magna Coated’ (or similar) which as well as zinc has aluminium and magnesium to provide up to 20 times more corrosion resistance than ordinary pre-galv steel tube.

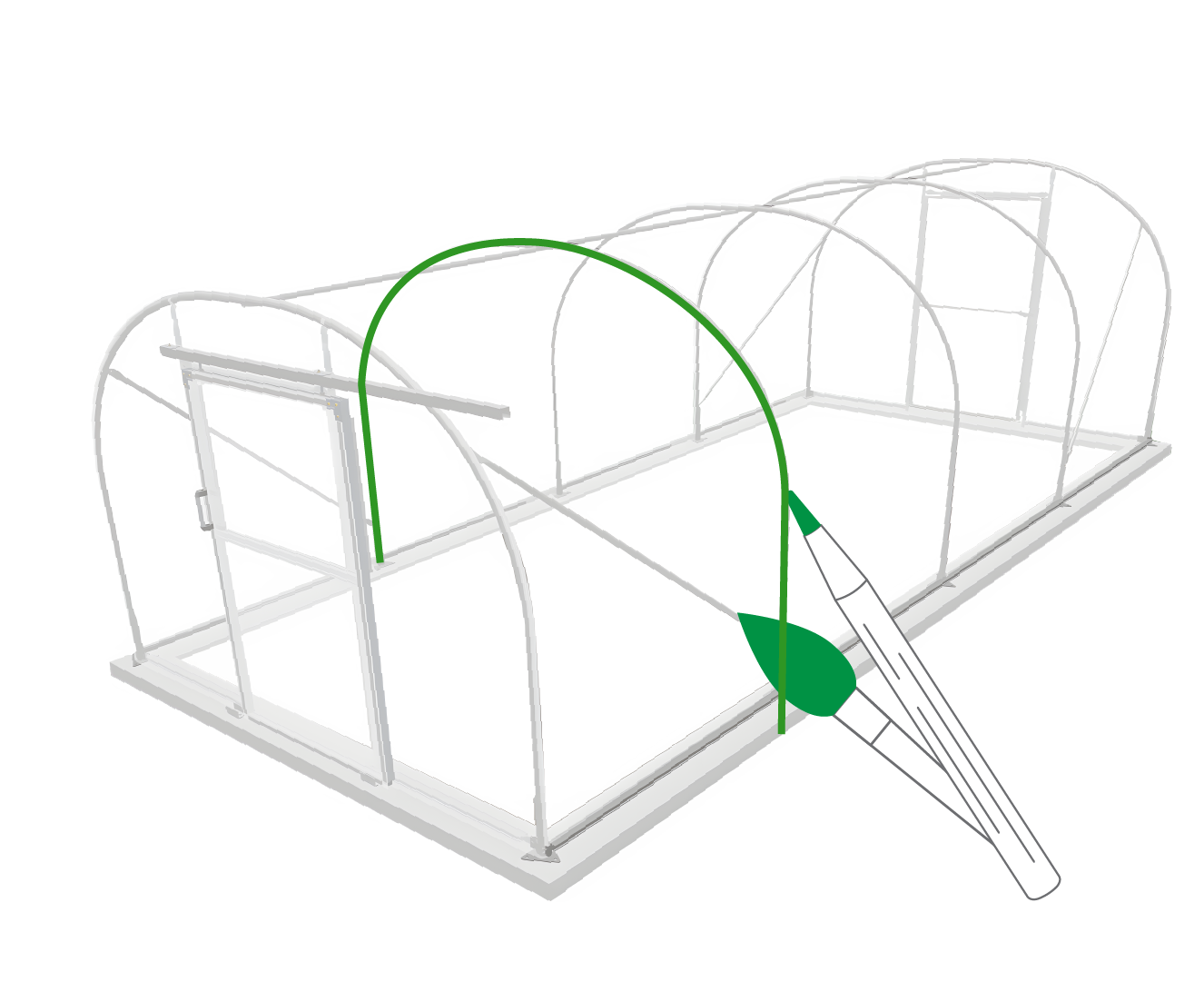

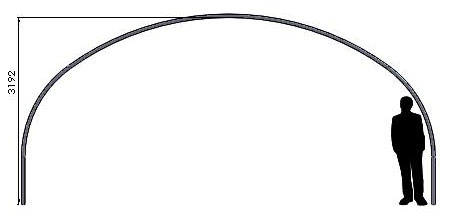

Hoops:

60.3mm diameter x 2mm wall thickness high tensile hoops at 2m centres.

Ridge bars, roof end braces and corner brace bars:

50.8mm diameter x 1.5mm wall thickness high tensile steel.

There are eight brace bars.

Foundation tubes:

54mm diameter x 2.5mm wall thickness (1500mm long).

Our foundation tubes sleeve inside the straight leg of each hoop to reinforce it (where it is under most stress in wind).

Height

Please note the ridge height shown assumes the bottom of the hoop would be at ground level. Typically the hoop is lifted off the ground by around 20cm to allow for fitting of aluminium cladding rails to the foundation tubes, increasing the height by 200mm.